Production Line

Chongqing Fuji Elevator Co., Ltd. has established a 50,000-square-meter intelligent manufacturing base in Liangjiang New Area, Chongqing, leveraging its three strategic platforms of digitalized management, intelligent products, and smart production.

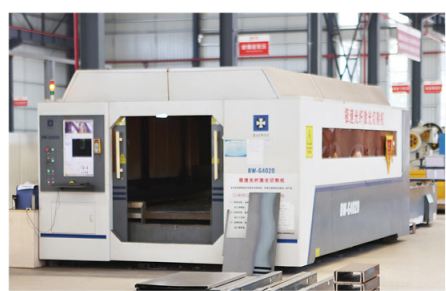

The production workshop features U-shaped lean manufacturing lines equipped with world-class facilities including German TRUMPF fiber laser cutters, Japanese YASKAWA welding robot clusters, and Swiss ABB painting robots, achieving 92% automation rate in key processes.

With 5G private network enabling equipment interconnectivity, the deployed MES and digital twin platform can monitor over 2,000 real-time production data points. The smart warehouse utilizes stacker cranes and vision-guided AGVs, improving material handling efficiency by 40%. For quality control, precision instruments like CMMs and laser trackers ensure critical dimensional tolerances within ±0.1mm.

The company has formed a smart manufacturing team led by 30 senior engineers and established a joint innovation center with Chongqing University’s State Key Laboratory of Mechanical Transmission, obtaining 12 patents in elevator guide rail processing and car assembly. This production line combining German equipment, Japanese management, and Chongqing smart manufacturing has increased annual capacity to 15,000 elevators while reducing delivery time by 35%.

Automated Paint Spraying Room

Fully Automated Door Frame Production Line

Fully Automated Flexible Door Panel Production Line

Fully Automated Reinforcing Rib Production Line

Fully Automated Reinforcing Rib Production Line

Ultra-Fast Fiber Laser Cutting Machine

wk01

wk02

wk03